Our Products

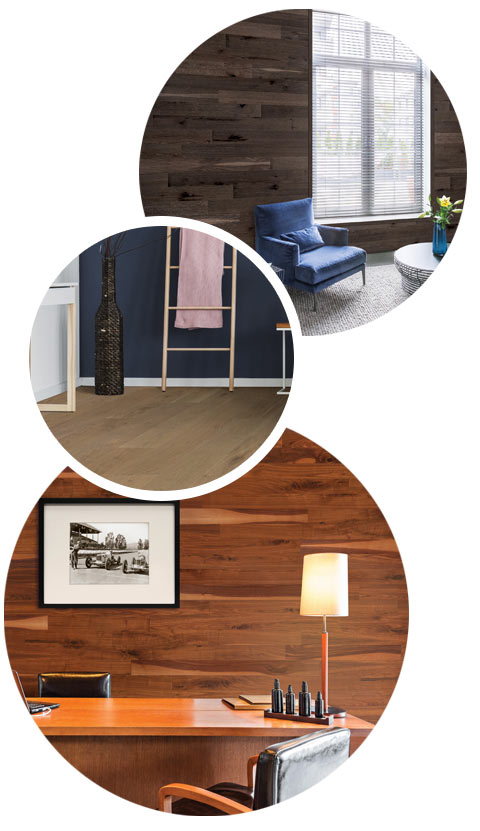

Trustor Coatings engineers and produces performance coatings for manufacturing of prefinished products.

Our Wearmax technology provides superior wear-resistance. These environmentally friendly products are compatible with a variety of substrates.

We offer clear and pigmented protective coatings, including:

- Primer

- Sealer

- Filler

- Putty

- Topcoat

We have a wide variety of coatings available for virtually any application method. Our coatings can be formulated to work with a number of application methods, including:

- Roller Coat

- Spray Coat

- Mist Coat

- Edge Coat

- Vacuum Coat

100% Solids Coatings

100% Solids coatings contain little to no solvent, so virtually 100% of the applied coatings converts to dry film on your substrate.

The resulting benefits compared to conventional oil or solvent-borne coatings include:

- Easier Regulatory Compliance (very low VOC)

- Energy Savings (Less energy cost to UV cure than to evaporate solvents or water)

- Environmentally Friendly (reduced waste, very low VOC)

- Improved Finish Quality (Scratch, stain and wear resistance properties)

- Improved Productivity (reduced waste, less frequent cleanup required, allows higher line speeds)

Waterbase Coatings

Waterbase coating formulas replace most (if not all) solvent with water.

The resulting benefits compared to conventional oil or solvent-borne coatings include:

- Performance is similar to or better than conventional coatings

- Appearance is similar to conventional coatings

- More environmentally friendly than conventional/solventbase coatings

- Low or No VOC

- Safer than conventional/solventbase coatings (no flammability, limited chemical exposure)

Waterborne UV Formulas

Waterborne UV formulas combine some of the benefits of 100% Solids with the application methods and equipment of conventional coatings.

The resulting benefits compared to conventional oil or solvent-borne coatings include:

- Catalyst free

- No Pot-Life constraints

- Increased throughput

- Appearance is similar to conventional coatings